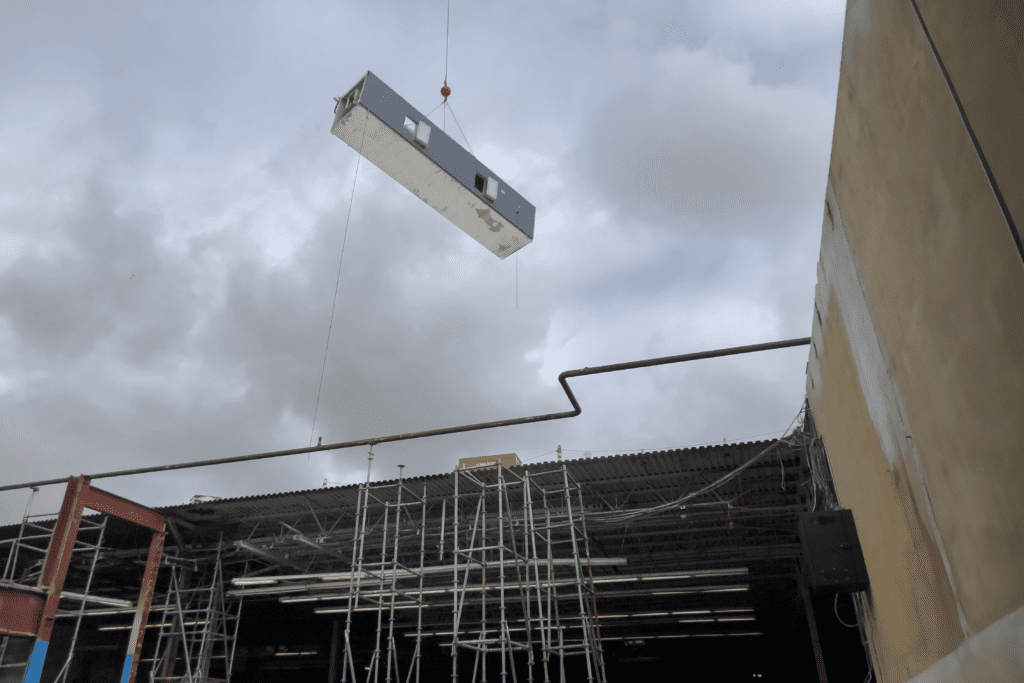

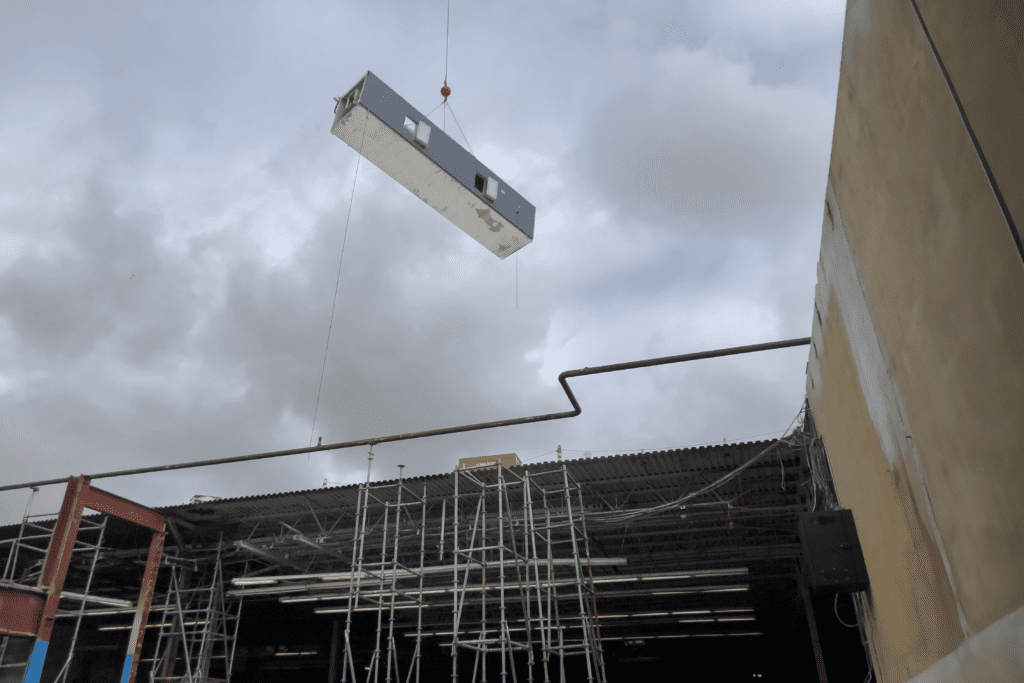

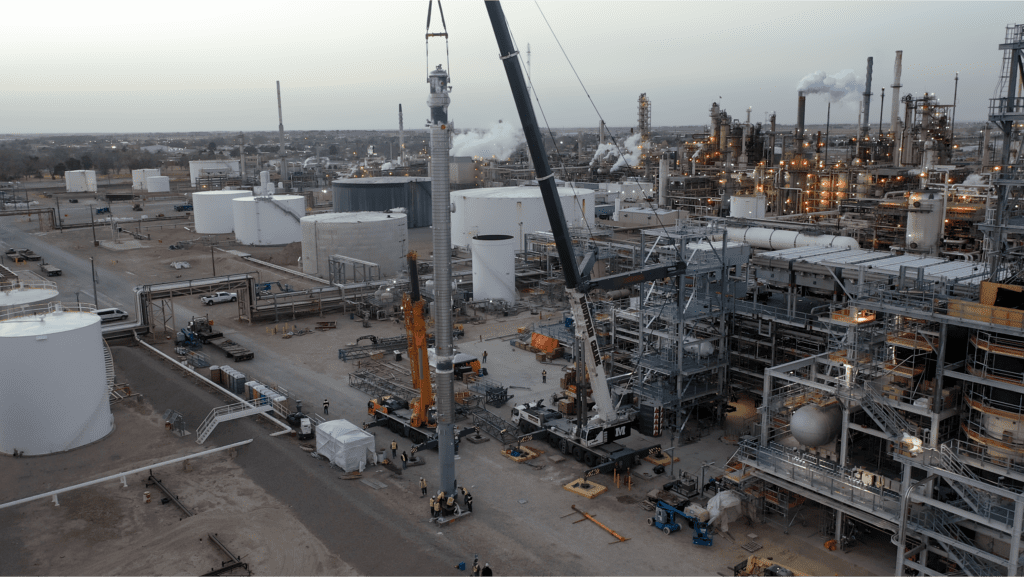

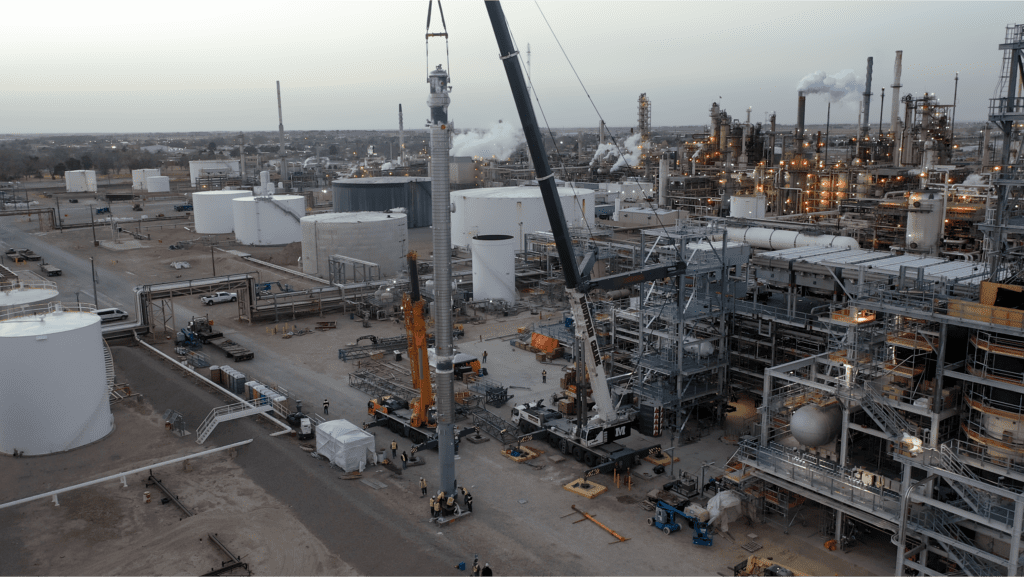

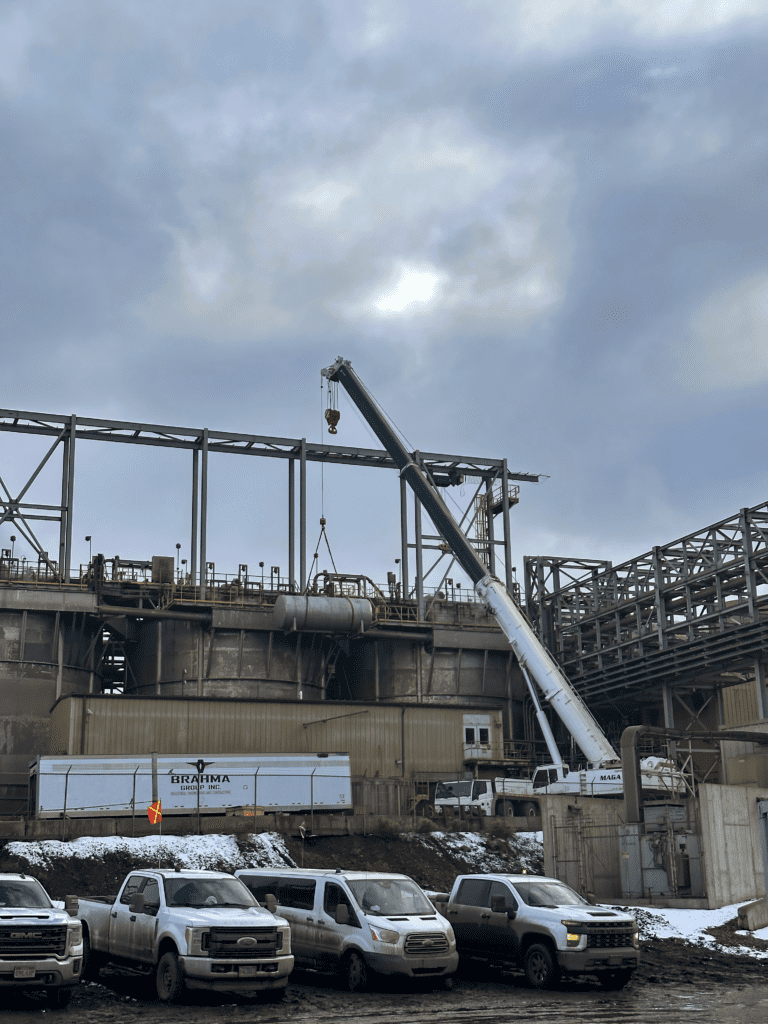

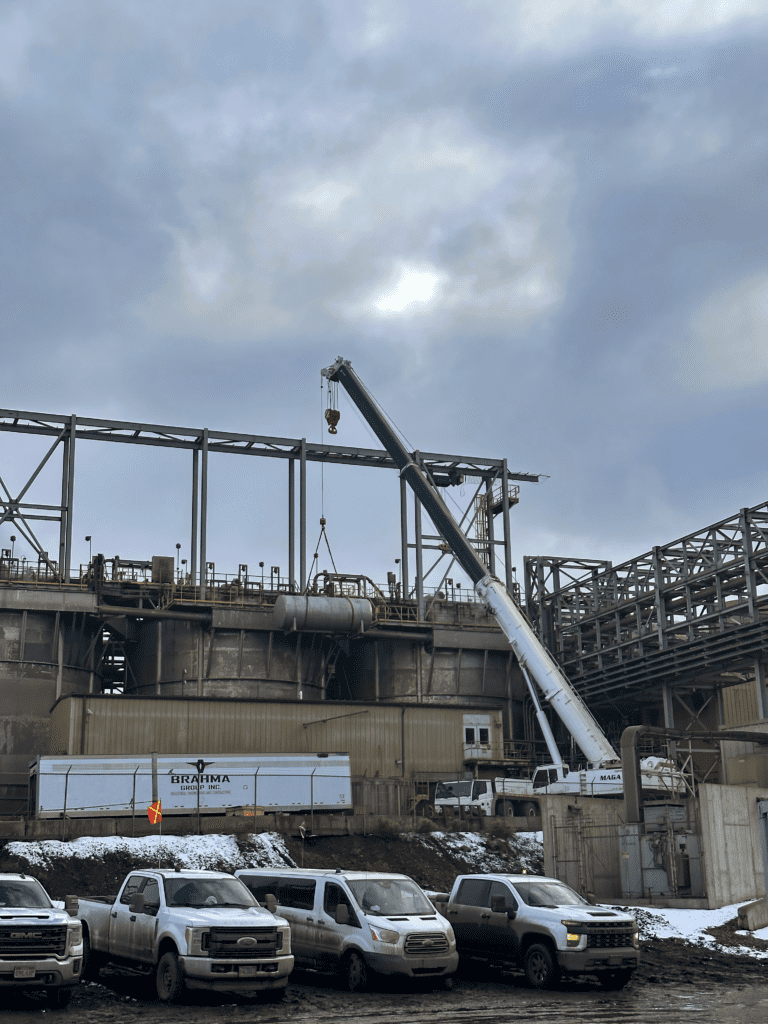

This two-year project involved significant upgrades to a booster pump station, including structural steel erection, pipe fitting, welding, and concrete work. Challenges included working in winter conditions and performing tasks high above the processing location.

Brahma Group is your trusted partner in industrial construction services, combining expertise, innovation, and an unwavering commitment to excellence.

© Copyright 2025 Brahma Group Inc. Powered By Social Hustle.

VP of Operations

VP of Operations

Meet Craig, a seasoned leader with over 26 years of management experience and technical expertise. His areas of specialization encompass a wide range of industry sectors, including project management, industrial facilities maintenance, plant maintenance, building and equipment structures, and construction management consultation.

Craig is certified in heavy rigging, with extensive experience in equipment removal and installation. His expertise extends to structural detailing, fabrication, erection, and installation. He also excels in conveyor system installation and maintenance, infrastructure improvements, capital project construction, bidding, estimating, and process piping and demolition.

Before joining Brahma, Craig honed his skills at Bell Steel, Inc. and Milling Machinery, Inc. His construction career, which began in the residential industry, eventually led him to industrial maintenance where he performed all aspects of millwright work. Craig’s commitment to continuous learning is evident in his completion of the ASU Alliance for Construction Excellence Project Management Course. He holds an OSHA 510 certification, a certification of completion in the Program of Project Management, and is trained in Auto CAD and Structural Steel detailing. With his vast experience and multitude of certifications, Craig brings a unique blend of leadership, technical acumen, and industry knowledge to his role.

CEO

Meet Darren, a seasoned professional with an impressive track record spanning over 35 years in project management, engineering, and industrial facility management. His career is marked by proactive leadership in steering complex projects across various industries. His strategic approach to staffing, maintenance, and operations has consistently ensured optimal performance and cost-effectiveness.

Darren’s journey has taken him through notable companies such as NV Energy at the Reid Gardner Station, PacifiCorp- Huntington Plant, Abitibi Consolidated, and Geneva Steel Company. Each role has contributed to his rich tapestry of industry experience and technical expertise.

Known for his exceptional contract administration skills, Darren excels in resource management, delivering quality products at reasonable costs. His foresight allows him to identify potential problem areas early on and implement viable, cost-effective solutions. His commitment to meeting budgets and promoting safe, productive work environments is unwavering.

Darren holds a Bachelor of Science in Electrical Engineering, which forms the foundation of his technical acumen. Leveraging his top-tier education and extensive experience, Darren ensures that project teams adhere strictly to contract specifications. He vigilantly monitors contract performance, ensuring safe work practices, regulatory compliance, and adherence to budget and schedule constraints. Under Darren’s watchful eye, every project has been a testament to efficiency and quality, completed on time and within budget, with post-outage equipment performance exceeding expectations and installations meeting established technical standards.